INDUSTRIAL ELECTRICAL

ELECTRICAL CONTROL SYSTEMS

Electrical Control Systems

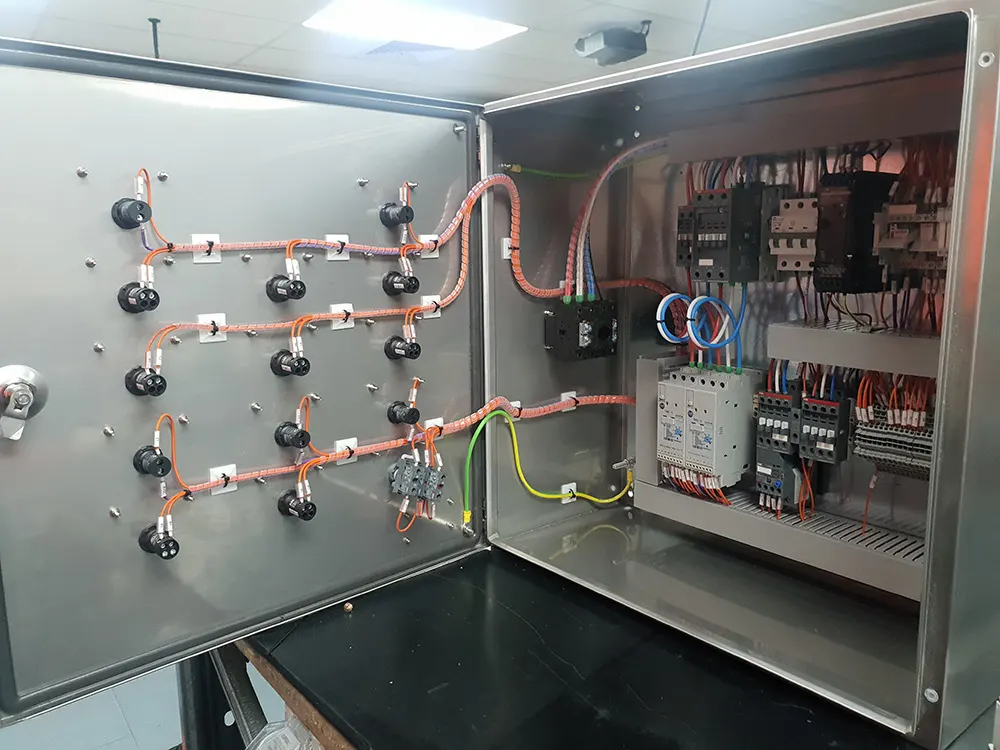

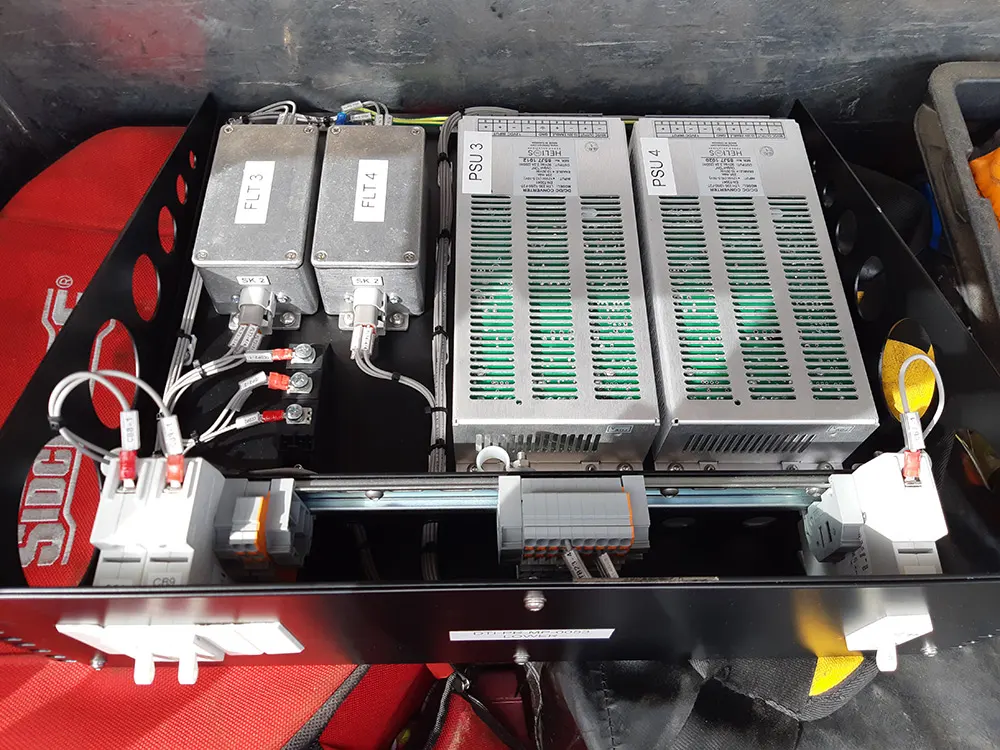

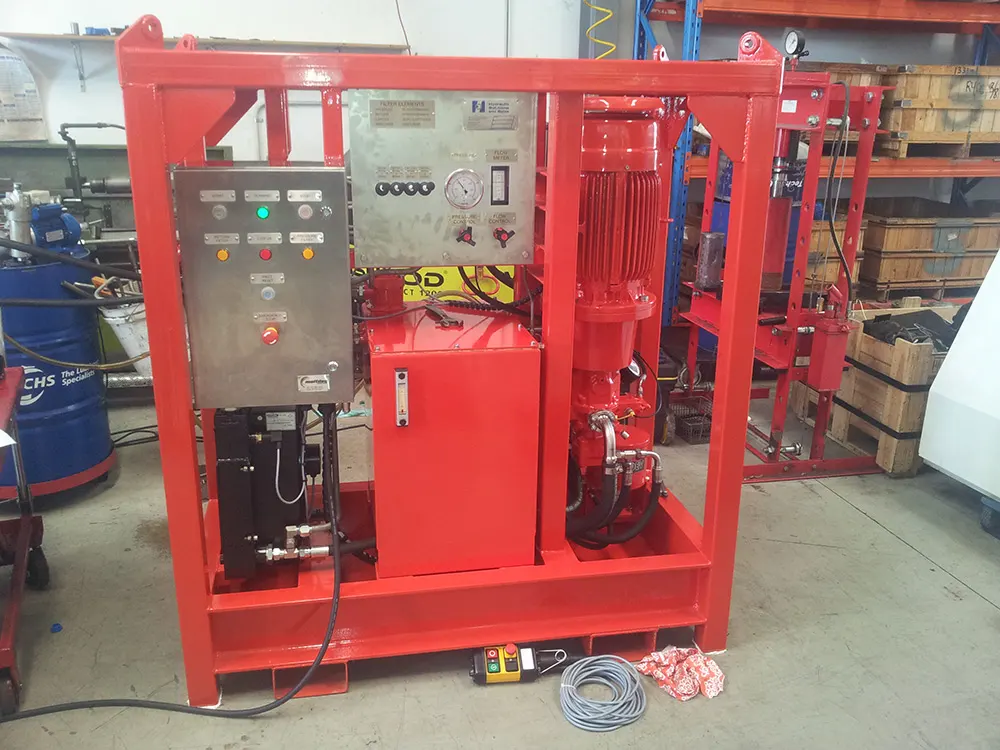

Multilec specialise in the design, manufacture, and installation of bespoke electrical control systems and panels. Our systems can control a wide range of mediums including water, air, hydraulic, glycol, diesel, and sewage—delivering reliable process control across diverse applications. We provide a true turn-key service, managed end-to-end in house: drafting schematics, procurement, panel fabrication, testing, and PLC programming where required. We work with your preferred brand or make, aligned to your specification or budget, and complete installation, testing, and commissioning onsite—locally or remotely.

What we deliver

Our primary objective is to fully understand your operational needs and provide the best tailored solution—working with clients through a collaborative approach that builds long-term success. We design and fabricate custom control panels in stainless steel, mild steel, GRP, plastic, or aluminium, including Hazardous Area rated Ex e or Ex d enclosures.

We build and program PLC control systems using a wide range of platforms, including Allen Bradley, Panasonic, Omron, Mitsubishi, Automation Direct, Red Lion, Schneider, Danfoss Plus 1, and IFM. We also supply electric motor starter panels such as DOL (240/415VAC), soft starters, and VVVF variable speed drives.

Whether you need a brand-new installation or an upgrade, Multilec can modernise existing relay-logic panels, add safety relays, and supply full AutoCAD Electrical documentation—GA layouts, termination details, and I/O schedules.

Industries Served

- Petrochemical

- Electricity transmission

- Oil & gas, water and wastewater

- Manufacturing

- Agriculture

FAQs

How many push buttons can I have on a handheld transmitter?

There is option for 8 or 12 push buttons.

Can I drive a hydraulic power unit solenoid coil?

Yes, we can configure the receiver to directly control a proportional (PWM Current) or On/Off coil.

Can you customise a transmitter for our application?

Yes, almost every system is customised to some degree, typical changes include labelling and output configuration.

I have an existing system that I would like to replace, is this possible?

Yes, we can reverse engineer an existing system to offer a new solution.

What voltage does the system require?

Typical supply voltage is 12 or 24Vdc, however the systems work on a wide range of 8-30VDC.

Is there a Hazardous Area ATEX Ex options?

Yes, however only in the T70/1 and T70/2 Handheld transmitter configuration.

What is the radio remotes operation range?

Depending on the choice of internal or external antenna and installation conditions:

- Internal installation not recommended with internal antennas.

- External antennas should be installed vertically.

- As much higher and cleaner area as possible, free of obstacles.

- Try to have eye-view from transmitter to the antenna.

- Floor is an obstacle that decreases the radio length.

- That is why as much higher the antenna better for the radio length.

What type of radio system do you use?

In use is a 2.4Ghz Radio that is completely self-managed (no radio channels)

A system comprises of two transceivers but working together simultaneously.

There are no radio channels that need to be selected (like tradition sub Ghz systems, the 2.4Ghz system utilises networks.